mining equipment spares

Impact crushers are used in applications where heavy mechanical pressure needs to be exerted on a material, such as furniture-making rubber sheets, concrete slabs, steel beams, and other heavy equipment components. These powerful industrial tools exert tremendous pressure upon objects and materials. Impact crushers differ from vibratory impact cleaners in that they generate more pressure than vibratory cleaners do and they also travel further and are much stronger than vibratory tools. These crushing tools are often used in the industrial, construction, automotive, and marine industries. They are also used in applications requiring demolition, drilling, grinding, piercing, and cutting power.

Impact crushers and other impact cleaning equipment are manufactured by a variety of manufacturers. Some of these include General Electric, Goodrich, Hitachi, Wabco, Toshiba, Murray, Nissan, and International Harvester. There are many companies that specialize in the manufacture of impact crusher parts for general industry use. Among these are International Harvester, Wabco, and International Crane. Each of these manufacturers is characterized by its own distinctive characteristics, including the types of compressor systems, the types of drive units, the types of clutches or rollers, and the types of brushes.

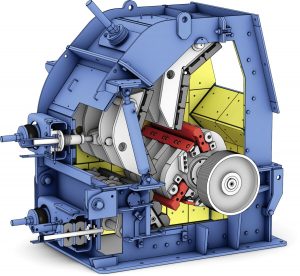

The various components that comprise an impact crusher system include: a high pressure source, a high pressure arm, and a high-powered brush or roller. The high pressure arm imparts force upon the material being crushed. High-pressure air or nitrogen is also used. High chrome steel alloy and aluminum alloy are commonly used in the manufacture of high-pressure arm and brush assembly. High resistant blow bar, nylon fabric, and aluminum fabric pads, rubber tires, and aluminum wheels are used in high-pressure air units and belts. The high resistant blow bar is designed to withstand high heat and stresses of continuous usage.

Impact Crasher Parts – Durable & High Quality Parts

Common impact crusher parts include bearings, air intake baffles, air filters, carbide tipped impact absorbers, claw feet, hydraulic pedals, piston rods, pinions, seals, timing mechanisms, timing belt assemblies, oil pumps, and many more. To ensure durability of impact crusher parts, they should be manufactured using materials that are resistant to corrosion, rust, and the effects of weathering. High quality parts should be warranted to withstand constant use under normal conditions.

Stone crushers have been in existence since the 19th century, so there are many different manufacturers in this field. All such crushers employ high-quality parts and are made from durable materials. They are perfect for use in crushing plants and powerhouses. Among the different types of stone crushers are:

Impact crushers are used for various purposes by crushing plants. However, improper usage can reduce the performance and can even cause the crusher parts to wear out. For example, using a single-speed chuck while cutting down soft-tissue trees can lead to premature wear of the transmission gearbox, clutch, and brakes. So, for enhanced performance and for prolonging the impact life of your cutting tool, always make sure you buy high quality spare parts.